EVATS 1000 - 1 pLC

PRODUCT RANGE

Fully Automatic Botlling Equipment

SEPPA Private Limited is one of the members of Shivsu Group of

Companies. SEPPA incorporates state of art technology

in design engineering of the system being manufactured by them.

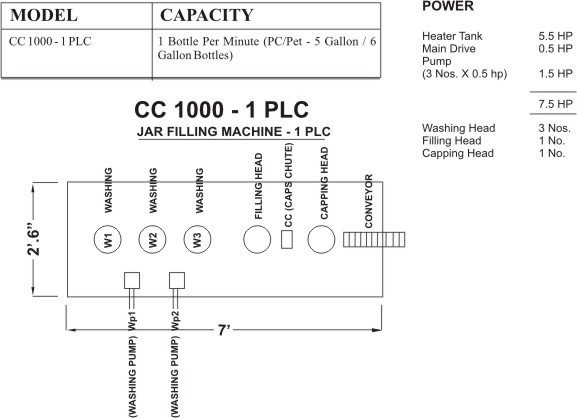

The Evats1000 PLC series consisting of 1 BPM to 24 BPM range has been specially designed and manufactured for 10 to 25 litres polycarbonate / PET bottles. The whole equipment is sleek and is capable of bottling various sizes of bottles, ranging from 10 - 25 ltrs. The mineral water bottles are fed to bottle holders, which tilt the bottle on top of high pressure spray which washes the bottle in 3 stages. In the first stage the bottles are cleaned with hot water detergent (temperature ranging from 55° C to 80°C). In the second and third stages the bottles are cleaned with ozone rinse water with a concentration of 0.4 to 1 ppm of ozone. The machine has Angular Spray for external wash of the bottle. After the cleaning stage the bottles are put on the filling conveyor. The filling is executed by a highly sensitive sensor activating a flow of water to the accurate predetermined measured quantity. The special feature in the system is that no water will flow in the system in the absence of bottles on the filling bay. After filling, bottles automatically move for the capping stage where the caps are released from the vibrator to the bottles and the bottles are sealed automatically using a capping head. The caps are also specially sanitized by ozone water jets. In short the Evats 1000 PLC is an unique bottling machine with in built high tech features. The entire system is enclosed in a stainless steel / glass outer casing. After the capping stage the bottles are automatically ejected out to the output conveyor.

Optional: Ozone Generator, Wash types and numbers can be changed on customer request.