10 - 12 - 16 - 24 PLC

PRODUCT RANGE

Auto

Loader

Auto

Loader

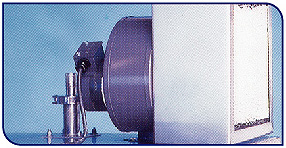

Fully automatic bottle loading system to load water

bottles from infeed conveyor to bottle holder. Advanced robot pneumatic

system combined with optical sensor makes the loading process reliable

and efficient.

Scrubber

Scrubber

Specially designed Nylo-Brussel Scrubber are provided in combination

with angular sprays to wash the outer surface of the bottle. The scrubber

is so designed even to clean the external neck area.

Automatic

Filling Valves

Automatic

Filling Valves

Stainless steel sanitary high accuracy filling valve

are used to achieve even filling in all mineral water bottles. Specially

designed high pressure and low pressure filling cycle is provided with

PLC control.

Washing

System

Washing

System

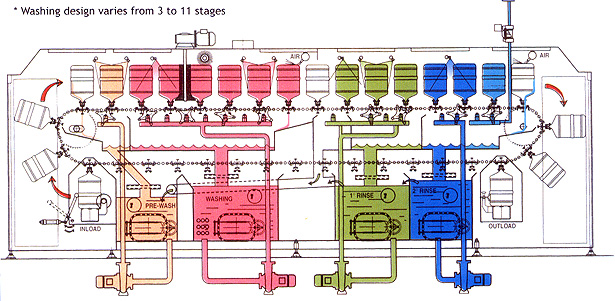

The Machine incorporates four types of washing

- Filter water wash

- Detergent hot water wash

- Hot water

- Ozonised water

Stage of washing is available from 3 to 11 depending upon customers requirements. Wash water recycle tank as well as 5/5 dust bin are provided in the washing segment.

Specially designed Nozzles with angular 0° to 15° ensure efficient

internal wash of the bottles.

Control

Panel

Control

Panel

State of art PLC is used with LCD display screen to control the machine.

This system control important functions like Wash Time, Fill Time and

Conveyer ON/OFF Time and also provide detailed fault detection features.

Clean

Room System

Clean

Room System

Built in clean room features with HEPA sub micron filter can be provided

on request.

Washing Cycle

System Profile :

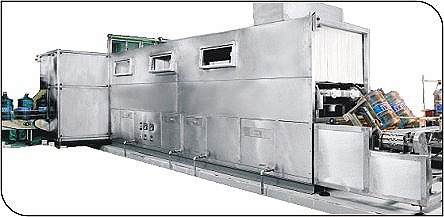

SEPPA Private Limited incorporates State of art technology in design engineering of the system being manufactured. The SEPPA 1000 PLC series consisting of 2 BPM to 24 BPM range has been specially designed and manufactured for 10 to 25 liters poly carbonate / PET Bottles. The mineral water bottles are fed into an automatic robot arm which tilts the bottle on top of high pressure spray which washes the bottle in 3 to 11 stages (Washing stages vary depending on quality request). The SEPPA Private Limited 1000 PLC series is designed to wash, scrub, fill and cap the bulk bottles.

Technical Specification :

Model |

Capacity |

| EVATS 1000-2PLC : 2 | 2 Bottles per minute (PC/PET-5 Gallon / 6 Gallon Bottles) |

| EVATS 1000-2PLC : 4 | 4 Bottles per minute (PC/PET-5 Gallon / 6 Gallon Bottles) |

| EVATS 1000-2PLC : 6 | 6 Bottles per minute (PC/PET-5 Gallon / 6 Gallon Bottles) |

| EVATS 1000-2PLC : 10 | 10 Bottles per minute (PC/PET-5 Gallon / 6 Gallon Bottles) |

| EVATS 1000-2PLC : 12 | 12 Bottles per minute (PC/PET-5 Gallon / 6 Gallon Bottles) |

| EVATS 1000-2PLC : 16 | 16 Bottles per minute (PC/PET-5 Gallon / 6 Gallon Bottles) |

| EVATS 1000-2PLC : 24 | 24 Bottles per minute (PC/PET-5 Gallon / 6 Gallon Bottles) |